Our Process

- Home

- Our Process

Discover How Disha Rack Manufactures High-Quality Storage Solutions

Explore the intricacies of Disha Rack’s manufacturing process. From meticulous design and material selection to precise cutting, welding, and surface treatment, we ensure each storage rack meets the highest standards of quality and durability. As the best rack manufacturer in Kolkata, we pride ourselves on our commitment to excellence and customer satisfaction. Our comprehensive overview delves into the steps involved in creating our top-quality storage solutions, emphasizing our dedication to precision, innovation, and reliability. Additionally, we are recognized as the best wholesale rack dealer in Kolkata, catering to businesses of all sizes with customizable solutions that optimize space and streamline operations. Discover the craftsmanship behind our products and why businesses trust us for their storage needs.

Design and Planning

The manufacturing process begins with careful planning and design. Our team of engineers and designers collaborate to create rack designs that meet the specific requirements and dimensions provided by clients. Factors such as load capacity, space constraints, and accessibility are taken into consideration during this phase.

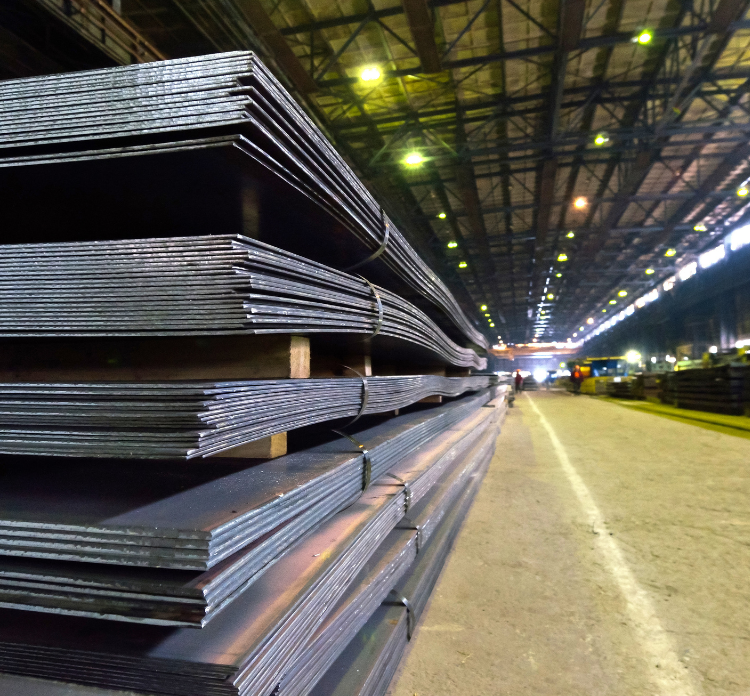

Material Selection

High-quality materials are essential for durable and reliable storage racks. We carefully select materials such as steel, aluminum, or other alloys based on the intended use and environmental factors. These materials undergo rigorous quality checks to ensure they meet our standards for strength, durability, and corrosion resistance.

Cutting and Shaping

Once the materials are selected, they are cut and shaped according to the design specifications. Advanced cutting tools and machinery are used to precisely cut and shape the metal components into the required sizes and dimensions. This ensures consistency and accuracy throughout the manufacturing process.

Welding and Assembly

The cut metal components are then welded and assembled to form the framework of the storage racks. Skilled welders use precision welding techniques to join the components securely, ensuring structural integrity and stability. Assembly may also involve attaching additional features such as shelves, braces, and support beams as per the design requirements.

Surface Treatment

Surface treatment is applied to the racks to enhance durability and appearance. This may include processes such as sandblasting, priming, and powder coating to protect the racks from corrosion, rust, and wear. Surface treatment also allows for customization of colors and finishes to match the client’s preferences.

Quality Control

Quality control is a critical step in the manufacturing process to ensure that the finished racks meet our stringent standards for quality and performance. Each rack undergoes thorough inspection and testing for dimensional accuracy, load capacity, weld strength, and surface finish. Any defects or inconsistencies are identified and addressed before the racks are approved for shipment.

Packaging and Shipping

Once the racks pass quality control checks, they are carefully packaged to prevent damage during transit. Packaging materials such as foam padding, bubble wrap, and corrugated cardboard are used to protect the racks from scratches and dents. Racks are then loaded onto pallets or crates and shipped to the client’s location using reliable transportation services.

Installation and Support

Upon delivery, our team provides installation support to ensure that the racks are assembled correctly and safely. We offer guidance and assistance throughout the installation process, ensuring that the racks are optimized for maximum efficiency and functionality. Additionally, we provide ongoing support and maintenance services to address any issues or concerns that may arise.